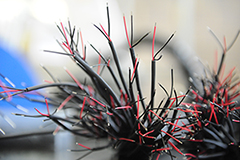

Precision Custom Cable Assembly & Wire Harness Manufacturing in the UK

St. Cross is your specialised UK manufacturer for bespoke cable assemblies and wire harnesses, serving critical sectors including Military, Aerospace, and Medical. Leveraging over 40 years of expertise and cutting-edge Komax automation, we deliver UL/ISO-approved interconnect solutions tailored for complexity - from fine-gauge 32AWG signal cables to high-power 150mm sq. looms. All manufacturing, inspection, and testing are carried out from our base in Southampton, ensuring premium quality and rapid turnaround times.

Quality Assurance and Industry Approvals

We guarantee the integrity of your interconnect solutions through strict adherence to established international and industry standards.

ISO 9001:2015 (QMS): Comprehensive Quality Management System ensuring consistent, high-standard manufacture.

ISO 14001:2015 (EMS): Commitment to environmental management and sustainability throughout our operations.

ISO 45001:2018 (OHS): Certified Occupational Health and Safety management system, demonstrating a priority on workplace integrity.

UL Approved (Since 2010): Highly acclaimed approval for the manufacture of cable harnesses in our UK plant, critical for product design, build, and traceability.

Specialist Compliance: Expertise in standards for demanding sectors, including TYCO System 25 practices for Military and Aerospace applications.

Traceability: Full batch traceability and comprehensive internal testing protocols (Continuity, Hi-Pot, Pull-Test).

Bespoke Interconnect Solutions: Your Long-Term UK Partner

Custom Design & Manufacturing: We provide complete interconnection solutions, specialising in bespoke cables, custom harnesses, and complex overmoulding.

The UK Advantage: By manufacturing entirely within the United Kingdom, we guarantee full supply chain control, faster reaction times to design changes, and consistent quality standards, delivering solutions on time and within budget.

Partnership Focus: Whether your requirement is for a rapid-turnaround one-off prototype or a long-term strategic manufacturing partnership involving scheduled inventory management, we offer flexible solutions scaled to your business needs.

Scalable Manufacturing: Batch Sizes and Technology

| Capability | Specification | Key Benefit |

| Batch Size | From 1 (Prototype) to 100,000+ (Volume) | Full scalability from initial design verification to high-volume OEM production. |

| Complexity | Simple point-to-point cables to complex harnesses with over 1,000 circuits | Ability to handle diverse technical requirements and system architectures. |

| Automation | Fully automated Komax robotic machinery | Ensures micron-level accuracy, high-speed throughput, and cost efficiency. |

| Wire Size Range | From micro-gauge 32AWG up to heavy-duty 150 mm sq. | Supporting delicate signal transmission and high-power delivery applications. |

Sector Expertise: Delivering Performance in Critical Environments

We specialise in cable assemblies and looms engineered for the most demanding applications and environments.

Aerospace & Defence: Compliance with TYCO System 25 for high-reliability, low-weight, and highly durable contra-helical looms required in avionic and ground support systems.

Medical: Traceability and sterile manufacturing procedures for harnesses used in diagnostic equipment and patient monitoring systems.

MotorSport (F1, Rally): Ultra-lightweight, resilient harnesses designed to withstand extreme vibration, high temperatures, and rapid-cycling stress.

Marine, Oil & Gas: Solutions featuring specialised IP-rated environmental sealing (e.g., IP68) and corrosion-resistant materials for subsea and hazardous area deployment.

Telecoms & Audio Visual: High-integrity assemblies for data, RF, and complex signal routing, ensuring minimal cross-talk and signal loss.

Design for Manufacture (DFM): Engineering Partnership

Our DFM process is an active collaboration that ensures your product is optimised for reliability, performance, and cost from the outset.

Engineering Collaboration: We integrate our 40 years of manufacturing knowledge directly into your design phase. By having our engineers consult with yours, we proactively identify and resolve potential production challenges.

Material and Component Specification: We eliminate costly compromises. We use our extensive experience and market knowledge to recommend materials and connectors (from delicate 32AWG signal wires to heavy-duty 150mm sq. power cables) that ensure peak performance while mitigating risks like long lead times and un necessary cost.

Cost-Reduction Focus: Our expertise allows us to recommend alternative, high-quality connector choices and efficient routing strategies that maintain integrity without requiring expensive, over-specified components.

CAD Integration: Our in-house CAD team works seamlessly with your existing documentation. We routinely process drawings and specifications from standard packages including SOLID WORKS, VISIO, and common industry file formats.

Process Efficiency and Expert Personnel

We combine four decades of collective staff experience with continuous investment in technology to deliver reliable, efficient manufacturing.

Lean Manufacturing Process: We employ a rigorous lean manufacturing approach, driven by a training matrix and monthly Key Performance Indicators (KPIs), ensuring continuous process improvement and optimal time management. This allows us to remain highly competitive without any compromise on quality.

Systematic Scheduling & Traceability: Production is meticulously scheduled using our internal MRP/ERP system, a robust process we've maintained since 1979. This daily systematic approach provides customers with reliable delivery forecasting and complete batch traceability.

Advanced Automation & Tooling: Our continuous investment programme focuses on sophisticated, automated tooling. We utilise robotic CNC machinery (such as Komax) to execute complex processes such as cutting, crimping, and automated inspection, delivering precision far beyond manual capabilities.

Veteran Expertise: Our assembly team boasts industry-leading longevity; many of our operators have been with the business for decades, ensuring every cable assembly benefits from a vast wealth of practical manufacturing experience.

Start Your Project Today

We are ready to partner with your engineering team to deliver bespoke cable assemblies built to the highest standards.

Request a Free, No-Obligation Quote: Contact our team with your specifications, volume requirements, and delivery timeline.

Schedule a DFM Consultation: Discuss your design challenges directly with our engineers to optimise performance and cost.

Send Us Your Technical Drawings: Email your specifications, CAD files (e.g., SOLID WORKS, VISIO, DXF), or technical drawings directly to our engineering team for immediate review.

Want to find out more? Get in touch now!

Contact one of the team today with your enquiry for free no-obligation quote.

Find out More - What Are Cable Assemblies?